No. 2A - Later ZAMAK

Obviously, this change was driven by the need to simplify

production process and by that reduction of the production cost.

In summary, the Hand Drill No. 2A Transitional shares some

characteristics of No. 2 - 1938 release and employs new design

element, later used in No. 2A - 1957 (ZAMAK) release.

The following

table illustrates construction element of 1938 design, migration

of some of these elements and new elements in No. 2A

Transitional. The third table shows migration of majority of these elements and new

elements in No. 2A - 1957 (ZAMAK) release.

|

No. 2 - 1938 |

No.

2A Transitional |

No. 2 - 1957 (ZAMAK) |

|

Iron Frame >

Spindle Size

Ball Bearing

Polished Spindle Hous. >

2 pinions >

Main Gear >

Chuck Design >

Main Handle >

Side Handle >

Crank Handle

Design >

Crank Handle Marking |

Iron Frame

NEW - Spindle Size

>

NEW - Ball Bearing

>

Polished Spindle Hous.

2 pinions >

Main Gear >

Chuck Design >

Main Handle >

Side Handle >

Crank Handle

Design >

NEW-Crank Handle

Marking> |

NEW

- "Zamak" Frame

Spindle Size

Ball Bearing

NEW - Painted Spindle

Hous.

2 pinions

Main Gear

Chuck Design

Main Handle

Side Handle

Crank Handle

Design

Crank Handle Marking |

The drill No. 2A Transitional is not seen on the second-hand

market very often. This suggest that the transitional

period was rather short.

The number of these drills available today is disproportionally

lower to the number of No. 2A-Zamak. Over last 3 years I

restored many dozens of No. 2A-Zamak drills. Over the same

time I have seen and purchased a dozen or so No. 2A

Transitional models.

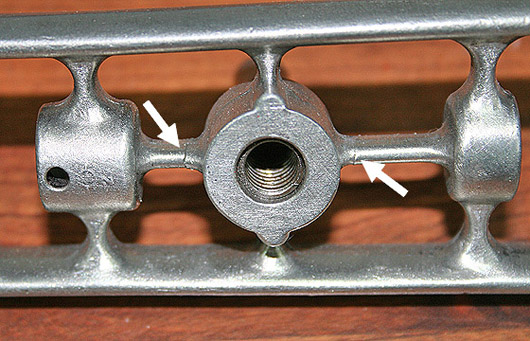

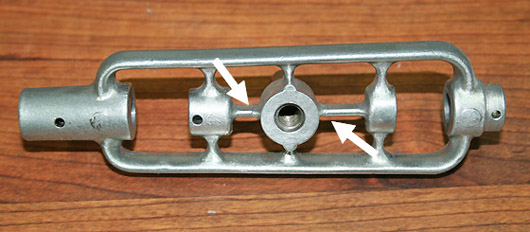

Inevitable question stands on how frame made in Zamak compares

with iron. Here are my observations.

Drills made in Zamak are prone to give in under substantial

stress. Below are photographs of the frame brakeage.

I have seen this problem too often.

Here is a typical No.2A-Zamak frame after clean up.

Marked with arrows are two areas of concern.