|

|

|

|

|

|

|

|

Millers

Falls Hand Drill No. 2A

Transitional

by Wiktor Kuc |

1 of 10

1 of 10

|

|

|

|

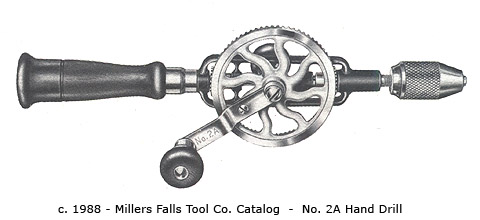

The hand drill No. 2A was introduced by Millers Falls Company

around 1957.(1) My

collection of catalogs does not go beyond 1949, consequently the

description of this drill is based on data from

the catalog

released by Millers Falls Tool Co., an entity organized in 1982.

The Ingersoll-Rand Company, the owner of Millers Falls Company

prior to 1982, sold all hand tool business to this new entity.

The description and image below is from the catalog published by this new

organization - a Millers Falls Tool Co.

Hand Drill No. 2A:

"Sturdy iron frame and machine cut gear with 4-1/2 : 1 gear

ratio. Hollow hardwood handle holds eight drill points:

1/16 to 11/64 included with tool. Main and side handles

made in tropical hardwood, stained and lacquered.

Side handle is detachable. Ball thrust bearing on spindle;

three-jaw, spring chuck adjustable from 0 to 3/8 inch.

Frame is enameled black and drive gear enameled red.

Bright parts are nickel plated."

Data Summary:

| Model

No. |

Design Type |

Frame

Bearing |

Chuck

|

Paint |

Handles

|

Length

Weight |

Standard Equip. |

Prod.

Dates |

|

2A |

2

pinion

1 speed |

Die-cast alloy

One Ball Bearing |

3-jaw, spring

0 - 3/8 inch |

Frame - Black

Gear - Red |

Stained Hardwood |

14 1/5"

2 1/5 lb. |

8

drill bits |

1957

1968 |

I have been fortuned to handle and examine in detail

many samples of MF Hand Drill No. 2A. In majority

of cases the drills look just as the one seen below.

Some later production batches included drills with tigerwood handle, covered with

reddish lacquer.

Major differences between this 1957 model and preceding 1938

edition are in the type of metal used for the frame, casting

method of the frame, the size and appearance of the frame,

and the spindle diameter.

|

The No. 2 drill released in 1938 and produced until 1957, (the

introduction year of No. 2A) is made of malleable cast

iron later machined to affect a few areas of the

frame.

The No. 2A drill was built differently. The unspoken truth

is that the 1957 model is not build of iron. The metal used was

an alloy, popularly know as "Pot Metal" or "White Metal".

The above catalog description or any other source known to me

conveniently avoids this subject. There is no record that

I know of describing precisely and identifying the type of metal

used by Millers Falls to produce No. 2A drill. For the

sake of clear distinction and to establish clear terminology I

presume

that the alloy used was

standardized "Zamak".

The casting was done in a die and this, in

combination with properties of ZAMAK, produced highly

accurate shape of the drill frame.

|

|

|

POT METAL AND ZAMAK Pot

metal, also known as white metal, die-cast

zinc, or monkey metal, is a slang term that

refers to alloys that consist of

inexpensive, low-melting point metals used

to make fast, inexpensive castings. There is

no scientific metallurgical standard for pot

metal; common metals in pot metal include

zinc, lead, copper, tin, magnesium,

aluminum, iron, and cadmium.

WIKIPEDIA

Zamak (formerly trademarked as ZAMAK[1] and

also known as Zamac) is a family of alloys

with a base metal of zinc and alloying

elements of aluminum, magnesium and copper.

Zamak alloys are part of the zinc aluminum

alloy family; they are distinguished from

the other ZA alloys because of their

constant 4% aluminum composition.[2]

The

name zamak is an acronym of the German names

for the metals of which the alloys are

composed: zink (zinc), aluminum, magnesium

and kupfer (copper).[2] The New Jersey Zinc

Company developed zamak alloys in 1929.

While zinc alloys are popularly referred to

as pot metal or white metal, zamak is held

to higher standards.

WIKIPEDIA |

|

|

|

|

|

|

The No. 2-1938 frame. The width of the outside beam is

0.3 inch. |

|

The No. 2A-1957 frame. The width of the outside beam is

0.5 inch. |

The appearance of the frame changed in comparison to the No.2

-1938 model. The outside beams of the

frame are much wider then in 1938 edition (see comparison images

above). I believe this change was introduce to compensate

for lower strength of the "pot metal" and the need to make frame

more sturdy.

(1). Millers Falls Home Page -

Website

of Randy Roeder |

|

|

|

|

1 of 10

1 of 10

|

|

|

|