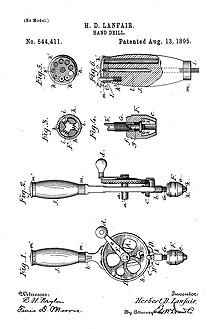

The Lanfair's

patent was awarded on August 13, 1895 under

No. 544,411 and

was assigned to Goodell Brothers Company. It included a design for a hand drill and several important

parts that constituted this drill. It was one of

the most important patents, secured by Goodell Brothers Co.

Some patented parts of the drill were easily adoptable to

other products that the company planned to produce. Herbert D. Lanfair described his invention as follows:

"My invention is an improvement in drills

chiefly for use of woodworking mechanics. It has for its object to provide a drill

mechanism which will easy to operate and multiply the

revolutions of the drill-bit with reference to those of the

crank.

"My invention is an improvement in drills

chiefly for use of woodworking mechanics. It has for its object to provide a drill

mechanism which will easy to operate and multiply the

revolutions of the drill-bit with reference to those of the

crank.

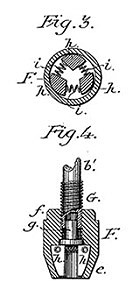

It consists essentially, first, of an

improved chuck for the drill wherein the drill-holding jaws

are separated by springs and held in place by housing

interiorly screw-threaded and adapted to engage a hollow

screw-threaded spindle. It consists, secondly, of an improved

drilling holder or handle for the drill wherein a screw-bolt

running through said holder centrally connects with a

disk-plate at one end and the frame of the drill at the

opposite end, the purpose of said construction being to

strengthen the said handle and thus improve its usefulness."

The importance of this patent

was long lasting for the future of the company. The chuck patented here was produced for

over five decades by

Goodell-Pratt Co. and later by Millers Falls Co. and for many more

years after that by many chuck makers in this and other

countries.

The importance of this patent

was long lasting for the future of the company. The chuck patented here was produced for

over five decades by

Goodell-Pratt Co. and later by Millers Falls Co. and for many more

years after that by many chuck makers in this and other

countries.

Another design, a friction plate or gear guide, used to

control pressure on a main gear against a pinion, was used on

many hand drills in Goodell-Pratt's line and continued by Millers

Falls Co. after 1931. Other improvements were used on

dozens of drills, made by both, Goodell-Pratt and Millers Falls

Co.

Interestingly, in the

Hammacher, Schlemmer & Co. catalog, the Goodell's tools were

placed next to Millers Falls Co. tools, but all the Goodell's

tools have a heading - "Goodell's". Millers Falls tools

don't

have any designation for the company and were simply

marked as "Hand Drill", "Breast Drill", etc.

Apparently, Mr.

Pratt had strong and convincing arguments for

Hammacher, Schlemmer & Co.

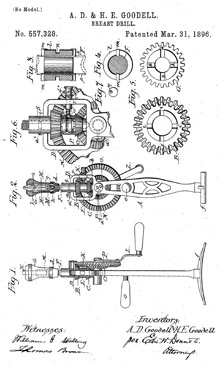

Another important tool shown in the same

catalog is the Breast Drill No. 6 and its variation, No. 7. It

was an important publicity for the Goodells, since it showed a 2-speed

drill with their own speed-changer

design.

Another important tool shown in the same

catalog is the Breast Drill No. 6 and its variation, No. 7. It

was an important publicity for the Goodells, since it showed a 2-speed

drill with their own speed-changer

design.

At the time it was a new design for breast

drills. Up to this point, change of speed in drills was done by removing

the main gear wheel and

placing it in the opposite socket that provided engagement for

the second

teeth layout on the gear-wheel.

This new design was authored by both Goodell brothers. Just like in the past, they joined their talents to do the work for

the company.

The patent was awarded on March 31, 1896, received

No.

557,328 and was assigned to Goodell Brothers

Company. It was another breakthrough patent for Goodell Brothers Company

and later for Goodell-Pratt Company.

The authors describe their invention as an improvement that...

The authors describe their invention as an improvement that...

"...consists in the main of metallic frame, and adjustable

breast-piece on one end of said frame, a chuck for a bit on the

opposite end of same and between said extremes, a system of

gear-wheels shiftable by means of a clutch to increase or reduce

the motion of the drill with reference to the motion of the

driving-crank and certain circular racks which engage the said

gear-wheels, all of which will be hereinafter fully described

and shown."

The concept of a two speed drill wasn't new, but the use of a

clutch and shifter to manipulate speed change was a different and new approach.

The implementation of this patent served the Goodell Brothers well

in the future development.

One of the tools incorporating the elements of this patent was a Hand Drill No. 5-1/2

- one of the most popular drills of the first half of the 20th

century.

The

Metal Worker, a weekly journal, published

one of the first reviews of the drill in October 31, 1896:

"Goodell Hand Drill No. 5-1/2.

"Goodell Hand Drill No. 5-1/2.

"Goodell Brothers Co., Greenfield

Mass., are offering their No. 5-1/2 hand drill, herewith

shown. The frame is of malleable iron, japanned; the gears

are all cut teeth and the handle is of polished hardwood

with a screw cap.

The chuck is three-jawed with a capacity

from 0 to 3/8 inch, and is provided with a nickel plated

knurled nut. A feature of the drill is the two-speed

device, the speed being quickly changed by aid of the nut at

F and S.

The slow speed, it is remarked, will be found

particularly desirable on large work, a fact that bicycle

repairers will appreciate. No drills (bits) are furnished with the tool."

Interesting circumstances surrounded the release of

this drill. In 1895 Millers Falls Co. released their

second version of a “new” hand drill No. 2. The announcement

came on June 20, 1895 in the Chicago Journal of Commerce and

Metal Industries:

“Millers Falls Company, 93 Reade Street, New

York and Millers Falls, Mass., have made improvement in

their No. 2 hand drill, as here shown.

Among the improvements is the addition of an extra handle,

to be attached when it is desired to use the drill in the

manner of breast drill. The handle is threaded on the end

and is screwed into the frame on the side opposite the

regular handle.

“Millers Falls Company, 93 Reade Street, New

York and Millers Falls, Mass., have made improvement in

their No. 2 hand drill, as here shown.

Among the improvements is the addition of an extra handle,

to be attached when it is desired to use the drill in the

manner of breast drill. The handle is threaded on the end

and is screwed into the frame on the side opposite the

regular handle.

The pattern of the chuck has also been

changed and is now arranged to carry three jaws instead of

two, as heretofore. The advantage gained in holding and

centering the points is emphasized by the company. Similar

chucks are now used on their Nos. 1 and 5 hand drills.”

As I previously noted, Herbert D.

Lanfair, the Goodell brothers' nephew, was employed by Millers Falls

Co. until 1895, when Henry E. Goodell and William M Pratt lured him to join Goodell Brothers

Co. Most likely he was the one, who provided Henry E. with

reliable information on upcoming release of a new drill by

Millers Falls Co. and it is feasible to assume that this

information was one of t he

motivators for such a rapid development of new tools at Goodell

Brothers Co. The release of hand drill No. 5-1/2 was

likely a competitive response to the Millers Falls Co.'s No.

2 drill release.

he

motivators for such a rapid development of new tools at Goodell

Brothers Co. The release of hand drill No. 5-1/2 was

likely a competitive response to the Millers Falls Co.'s No.

2 drill release.

Today some of the No.

5-1/2 drills receive a facelift and return to the "close to

original" functionality. Although the drill

in the photograph was made about fifteen years after

the first drills of 1896, its basic construction is the same.