Worthy of NoticeOne of continuing vulnerability of the No. 2

drill was the way main handle was attached to the frame.

This vulnerability manifested itself in cracks of the handle at

the point of attachment to the frame. It is especially

notorious on the drills introduced sometime after 1906 when

thicker handles were implemented, following changes in the frame

design. The new handle was much thicker at the point of

attachment to the frame and carried wider, stepped ferrule.

Here are some pictures showing the problem on

drill from c. 1938.

There are a variety of reasons for this persistent vulnerability and

they are analyzed in depth by George Langford in his No. 2 drill

type study. Spend some time on his web site at

GeorgesBasement.com - well worth it! In addition to

his finding, I believe there is one more reason for this

problem.

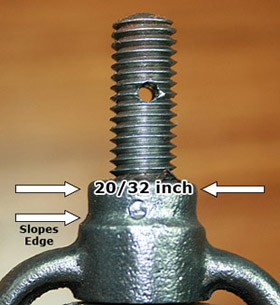

The outside diameter of the frame end, the tenon, is 20/32 inch but the

inside diameter of the ferrule is 24/32 inch. In addition,

the casting of this tenon does not have a sharp, 90 degrees

angle to the edge of the frame and existing

slope prevents a ferrule to fit snugly.

Consequently, the ferrule is a free-floating part that does not

serve its purpose. I believe

these parts should fit tight to each other and do not leave any

wiggle room. However, it is not the case on drills I have

examined. This creates overall pressures

distribution problem during the drill use.

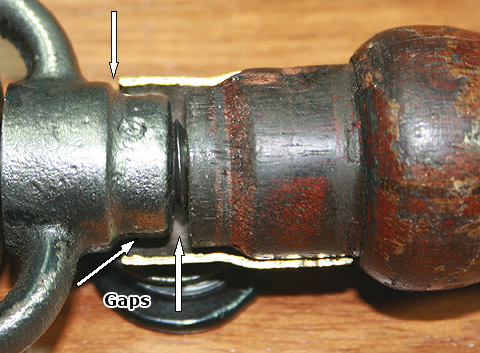

Here is a cut-out of the assembly. As you can see,

the work of controlling the drill is performed only by the

wooden handle attached to the threaded rod, without any support

from the ferrule or surfaces of the tenon and wood of the handle

touching together. In correct design and execution these gaps would be eliminated and provide

for much better distribution of pressure on wooden handle.