After some cleaning, polishing and painting the drill looks a

bit more friendly. The frame was cleaned, rust-proofed,

and painted with black, gloss enamel. I also painted the

gear wheel with red, gloss enamel and baked both parts in

the oven.

Here are all parts of the drill. I will review them in

detail.

The Frame

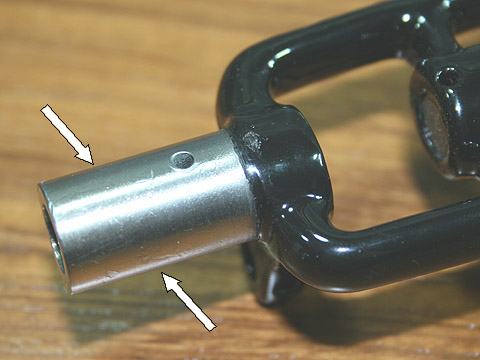

This is a view of the frame from the gear shaft side. I

polished the spindle housing, gear shaft and handle attachment screw before

painting. During painting these parts were protected with

masking tape.

This is a a view of the frame from the side-handle perspective.

The spindle housing is

5/8 inch in outside diameter and was originally nickel-plated.

After clean-up and polishing, the plating unfortunately did not

survive.

Now it is highly polished iron. The housing

has a provision for injecting lubricant.