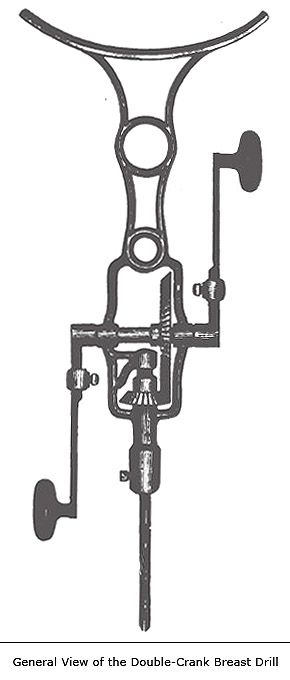

The double-crank breast drill recently put on the market by the

Millers Falls Company, 74 Chambers street, New York, has some

special features in its construction which, it is said, add

considerably to the efficiency of this style of tool, making it

more powerful and durable.

Little description is necessary beyond calling attention to the

accompanying cut, which presents a general view of the drill.

The power is transmitted to the drill through very heavy cut

gears, which are speeded about two to one.

Double cranks, which are adjustable to any length, and by which

the speed and power may be regulated as desired, allow of both

hands being used simultaneously in the operation of the drill.

The breast-plate is 12 inches long, and curved to fit the shape

of the body, thus preventing the tool from swinging around when

in use.

The hole in the spindle which receives the drill is ½ inch in

diameter.

The same company provides Morse twist drills of all sizes, with

½ inch shank, to fit this machine. They also sell a special

chuck which will hold all round and square drills below inch in

diameter.

The special features referred to above in the construction of

this drill in which the improvement lies are the new form of the

breast-plate, together with the double handles for rotating the

drill.

By the use of such a broad breastplate the operator can apply

pressure to the drill with more convenience and comfort, because

of the greater surface presented to the body; its curved shape

also prevents the tool from rotating when in operation.

By the use of the two handles much greater power can be executed

on the drill, besides distributing the work to both arms.

The method of altering the lengths of the cranks to which the

handles are attached is shown in the cut. The two set-screws

near the crank axis allow the cranks to be set at any desired

length, as the quality of the work requires.

The tool throughout is finely finished, the standard of cast

iron being lacquered, and the cranks, arms and chuck

nickel-plated.

Related Info