As the engineering public is gradually becoming educated to the

realization of the economy of keeping boilers clean, a

considerable number of devices have been patented to meet the

demand for a good tool to clean out flues.

Brushes have been tried, but the deposit which forms in flues

needs something more powerful than them for its effectual

removal.

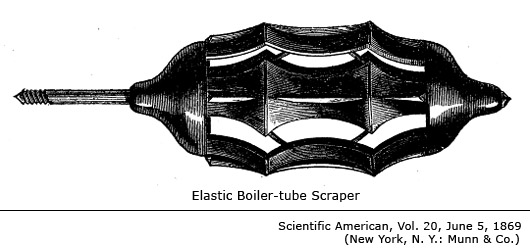

We last week illustrated an improved boiler flue scraper, and

this week we lay before our readers a description and engraving

of another device for the same purpose, the invention of Mr. E.

L. Pratt, deceased, late of Beverly, Mass., a patent for which

was granted to H. L. Pratt, administrator, May 11, 1869.

This scraper consists of two tapering heads, the broad parts of

each facing the other, fixed upon a pipe or rod at a short

distance from each other. The broad ends of the heads have

mortise-like recesses formed in them, which receive the ends of

the cutters; the mortises being large enough to admit

considerable play of the cutters to and from the longitudinal

axis of the instrument.

Each of the cutters has two cutting edges at right angles with

its longitudinal axis; so arranged that any part of the surface,

omitted by the forward one, shall be scraped by the other. These

are also contracted in the middle into a shape approximating the

section of an hour-glass, so that all the soot falls into the

central part of the instrument between the cutters, and is drawn

out with it.

The cutters are pressed out against the sides of the flues by

elliptical plate springs, which also permit the scraper to enter

and clean flues of various sizes. The cutters are to be made of

chilled iron which will render them very durable.

From the

cutting edges of the cutters extend, toward each head, ribs

which facilitate the entrance of the instrument; and they also

have a central rib extending between the cutting edges, which

facilitates the entering of the hinder cutting edges, while it

is sufficiently depressed not to interfere in the least with

their operation.

The scraper is so cheaply made that it is designed to furnish

them for every diameter of tube, and in such case, the cutting

edges are made to fit the curvature of the interior surface of

the flue. It is claimed that this scraper is cheaper, more

durable, and effective than any form of wire brush.

Orders should be addressed to Miller's Falls Manufacturing Co.,

87 Beekman St., New York city.

Scientific American, Vol. 20, June 5, 1869,

(New York, N. Y.: Munn & Co.)

Related Info

Wiktor A. Kuc

January, 2015

We want to hear from you - write to:

info@wkFineTools.com