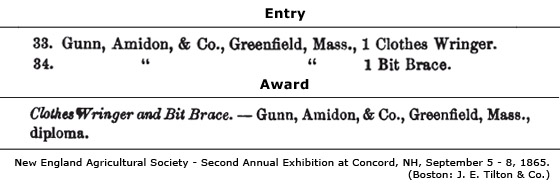

During

September 5 to 8, 1865 Gunn & Amidon

participated in the

Second Annual Exhibition organized by

the New England Agricultural Society in Concord,

NH.

They

presented two products - a wringer and a bit brace and

receive recognition in a form of diploma.

It is not

clear if the brace shown there was Barber's brace or a

new, Amidon's design. It would seem logical that

new brace of Amidon design was presented.

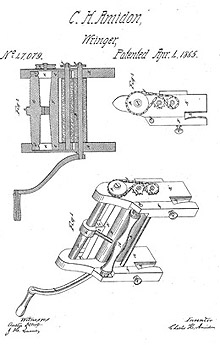

The

success of braces did not stop Amidon from

continuing improvements to his wringer. In August, 1865

he received another patent, No. 47,079, for Improvement

in Wringing-Machine.

The

success of braces did not stop Amidon from

continuing improvements to his wringer. In August, 1865

he received another patent, No. 47,079, for Improvement

in Wringing-Machine.

In the patent

description Amidon said: "Wringing or washing

machines are generally constructed with a bearings of

one roller placed in movable boxes, which are free to

rise and fall as the thick or thin body passes between

the rollers. Some are constructed with two cog-wheels,

one of which is attached to the end of the shaft of each

roller. Others have no gearing at all.

My invention consists in the manner in which I turned

the upper roller by means of an endless chain or belt,

operating in connection with three or more wheels, one

on the end of the shaft of each roller and one or more

attached to the frame-work of the machine."

Up to this point Amidon assigned both wringer patents to

himself and never transfer them to Gunn & Amidon company.

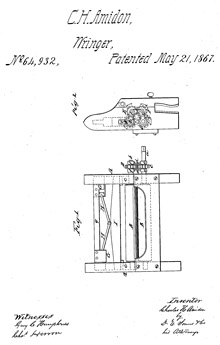

In May 1867, Amidon received another

patent for Improved Clothes-Wringer. This time

however, the situation was different. Amidon

assigned this patent to Bailey Washing and Wringing

Machine Company of Woonsocket, Rhode Island.

In the description Amidon points out the most important

feature as follows:

In the description Amidon points out the most important

feature as follows:

"The nature of my invention

consists in so arranging a wringing machine having

rollers composed of or covered with rubber or similar

elastic material or compound impervious to water, as

that the roller, which yields or gives to the varying

bulk of articles that pass between it and the roller

with fixed bearing, may move perpendicularly without

strain upon the gearing which connects the rollers, and

without causing the least alteration in relative

positions of the gearing-wheels their immediate

neighbors, while at the same time, from the peculiar

construction of self-adjusting spring, the pressure of

the roller upon the clothes is kept so nearly uniform

during all degrees of elevation or depression of the

roller that it may be considered practically constant."

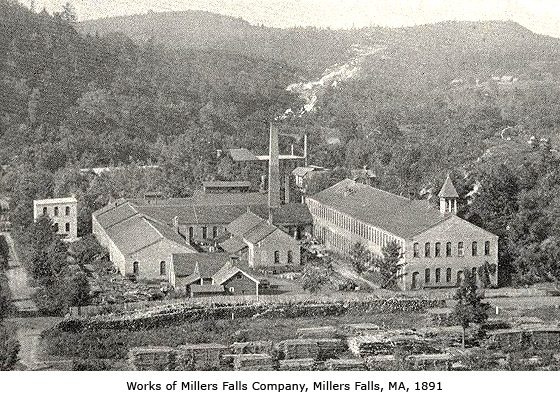

On December 31, 1868 the factory of Gunn & Amidon at

Cherry Rum Brook burned to

the ground.

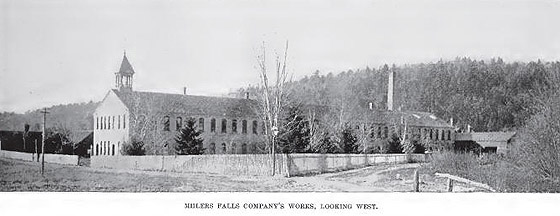

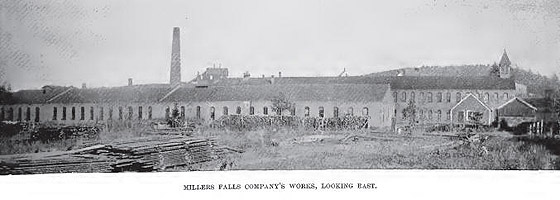

In 1892 the Greenfield Gazette, Centennial Edition published a

short review of Millers Falls Company, including rare

photographs of its facilities.

"The rapid growth of Millers Falls, which has made it one of the

prosperous villages of Franklin County, has been due almost

entirely to the Millers Falls company.

This company commenced business here in 1869. The promoters of

the enterprise were Levi J. Gunn; Charles H. Amidon and Henry L.

Pratt. Messrs. Gunn & Amidon had been engaged in the manufacture

of bit braces, wringers, etc., in Greenfield, and their factory

there was burned in 1868.

The water privilege and a considerable tract of land were

purchased at Millers Falls. The original shop was a one-story

brick building, 350 feet in length. There were also several

small out-buildings. The plant has been enlarged from time to

time, the shops now covering several acres, and having floor

space of 75,000 square feet.

The extent and capacity of the main buildings may be seen in the

accompanying illustrations. When a corporation was formed Mr.

Amidon withdrew, and is now located at Buffalo, N. Y. The

company was originally the Millers Falls Manufacturing Company,

but in 1874 it absorbed the Backus Vice Company and became the

Millers Falls Company. It has a capital stock of $200,000. The

factory gives employment to about 300 hands.

The goods manufactured are machinists' and household hardware,

beside many specialties. Leading lines are bit braces, breast

drills, angular borers, chucks of various kinds, hand drills,

automatic borers, angular drilling machines and various devices

for boring and drilling; anvil vises, machinists' and

wood-workers’ vises, jack-screws, Rogers, Lester, Goodell

companion and cricket scroll saws, family tool chests, saw

frames, carving tools, auger handles, hollow augers, family

grind-stones, soldering sets, wood and iron levels, glass

cutters, Crispin awls, screw drivers, hack and butcher saw

frames and blades, mitre boxes, mitre planers, wagon jacks,

nail-pullers, ratchet drills, wrenches, tool cabinets, and any

other articles which may be demanded by the trade.

The goods are sold in all the markets of the world, no

inconsiderable portion of the out-put being required for

importation.

The business has been uniformly successful. The president of the

company, Henry L. Pratt is located at 93 Reade Street, New York,

where the company maintains a large warehouse. Levi J. Gunn has

been the company's treasurer from the start, and George E.

Rogers, the clerk, has held that position for several years.

Much of the success of the company is due to the good management

of these officials.

The following is the full list of officers: President, Henry L.

Pratt; treasurer, Levi J. Gunn; secretary, Geo. E. Rogers;

directors, Henry L. Pratt, Edward P. Stoughton, John L. Varick

and George Munson of New York, Levi J. Gunn, Chester C. Conant,

Geo. A. Arms, Edward E. Lyman and Geo. E. Rogers of Greenfield."