It would be only a speculation to assume that the deal

to purchase Barber's patent was struck right there

and then, but the fact is that Gunn & Amidon began

production of bit braces in 1864.

Although the

patent was not assigned to "Gunn & Amidon", it is

generally assumed

that the deal included exclusive use of the patent,

production rights and use of Barber's name. On

February 6, 1872 however, the patent was reissued under

No. 4,736 and the Millers Falls Mfg. Co. reestablish

itself as an assignee, by mesne assignment, for

Barber's patent. Second reissue on August 15, 1876

confirmed Millers Falls Company as an assignee of the

patent.

Today, some believe that Gunn and Amidon did not fully

understand the significance of the Barber's design and

it was more or less a lucky choice that guided them in this

purchase. However, aside from luck, and considering Gunn's and Amidon's

experience in tools production and unquestionable genius

of Amidon in tools design, I believe it was conscious

decision and both partners understood from the beginning

the importance of Barber's patent.

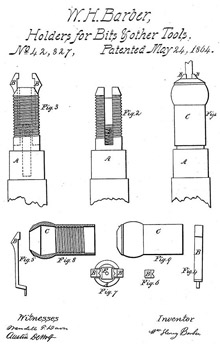

William Henry Barber received his patent on May 24, 1864

under No. 42,827. In his invention description

Barber said in part:

"Be it known that I, William Henry Barber, of

Greenfield, in the county of Franklin and State of

Massachusetts, have invented a new and useful instrument

for holding bits and other tools securely without

fitting the same to the holder; and I do hereby declare

that the following is a full, clear and exact

description of the construction and operation of the

same, reference being had to the annexed drawing."

The ingenuity of the design rests in its

simplicity and ability to accept bits with tapered square

shank of various sizes. These sound like a bottom-line

requirements but closer look will help understand Barber's

solution.

The ingenuity of the design rests in its

simplicity and ability to accept bits with tapered square

shank of various sizes. These sound like a bottom-line

requirements but closer look will help understand Barber's

solution.

He described it as follows: "The

instrument or holder consists of center piece, (marked A,) two

jaws, (Marked B and B,) a screw or nut, (marked C,) and a spiral

spring, (marked D.)"

First, the chuck consisted of only 4 parts: a

threaded shell, 2 jaws and a spring. After these parts

were produced, the assembly required no special skills or

equipment and could be performed by any worker or apprentice.

Second, at the time, the most popular bits were

made with tapered square shanks. They were made by wide

variety of producers, from small village blacksmith shops to

small and larger machine shops to larger production enterprises.

However, no standard existed and due to variety of production

methods and skills, the shanks were not exactly the same in size

and shape. Quite often the bit and brace users had to

custom-fit shanks to the chuck by filing and shaping them.

Barber's chuck was flexible and did not required shanks of the

same exact size.

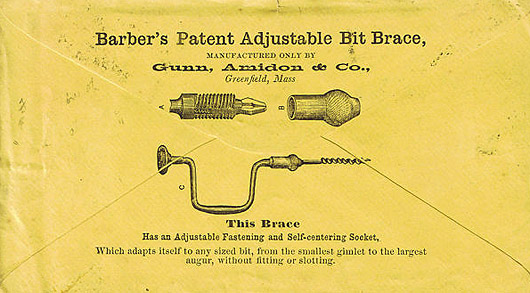

By 1865 production of bit braces was in full swing.

The choice made

by Gunn and Amidon was an instant success and positioned the

company well in the boring tools market.

This early investment propelled them into tool making

business.

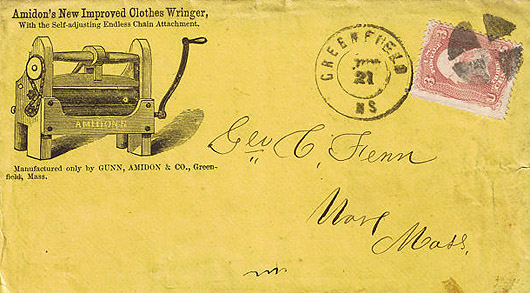

Envelope used by the Gunn, Amidon & Co. for

promotion of their core products.

Amidon immediately began experiments with his own chuck

design and on October 3, 1865 received patent No. 50,214

for Improvement in Bit-stock. He described his

invention as follows:

Amidon immediately began experiments with his own chuck

design and on October 3, 1865 received patent No. 50,214

for Improvement in Bit-stock. He described his

invention as follows:

"The nature of my invention consists in providing a

bit-stock with a movable socket-block to hold the head

of the bit from turning in the stock, in combination

with a pair of movable jaws to grip the shank of the

bit, and a screw-nut or sleeve to operate both socket

and jaws at one operation, thereby securing not only

great facility of action, but greater steadiness and

truth than is commonly attained."