Drill No. 2A Transitional Construction Elements

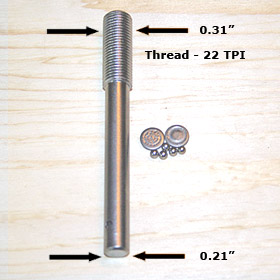

This variation in ball numbers was dictated by different diameter of the spindle

and spindle seat used in the drills over the years. The

spindle diameter on No. 2-1938 is 0.21875". The No. 2A -

Transitional returned to spindle diameter of 0.25", used on models

from 1895 up to 1920. With larger diameter of the spindle

the ball bearing in No.2A Transitional was also changed to one

ball without races and then carried forward to No. 2A - Zamak

and later models.

Spindle and Ball Bearing on No. 2 - 1938 |

|

Spindle and Ball Bearing on No. 2A -

Transitional |

The change in the spindle diameter and thread size required change in

a chuck as

well. The chuck used on 1938 No. 2 drill was designed and

patented by Henry A. Ryther, an employee of Millers Falls Co.

The patent receive No. 1,470,197 on October 9, 1923.

It was one of the best, if not the best,

chuck designs of the era.

The same chuck was used on No. 2A Transitional drill

and continued on the later, 1957 version. Obviously, the

opening was changed to the 0.25 inch and the thread to 24

TPI.

On the left - Chuck from No. 2 - 1938 drill. On the right

- chuck from

the No. 2A Transitional drill.

Chuck from the No. 2A Transitional drill.

Another significant change occurred in the main handle mounting

parts. However, this change was initiated in later version

of 1938 model, most likely in early 1950s. The original 1938 No. 2

hand drill continued with

concept used previously on drills from models released between 1903

and 1935.

These

were the drills that employed a friction roller at the

top of

the single pinion and main gear.

All these drills were designed with a threaded stem at the end

of the frame. It served as a mounting screw for main handle. Although the

opening in main handle was not threaded, it was screwed on using

moderate force and pinned to the stem through the handle's ferrule.

With 1938 model the frame was redesigned to accommodate second

pinion. The system had to be created to

provide a way to secure the pinion and main handle

in place of previous threaded bolt.