Three of the bestselling drills of the Millers

Falls Co., Millers Falls, Mass., are known as their No. 210

Bench Drill, No. 1980 Hand Drill and No. 97 Breast Drill.

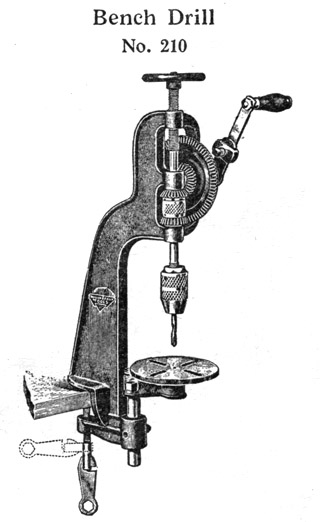

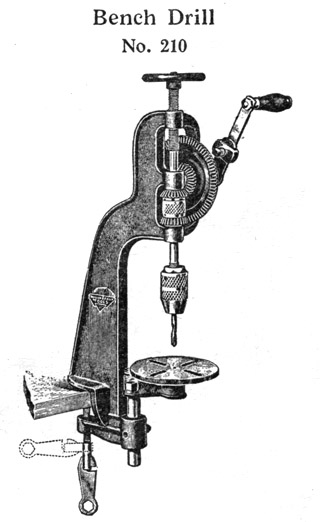

The bench model is stated to be the largest

selling drill press of this type made by the company and it is a

thoroughly efficient tool sold at the reasonable price of $15,

which gives it unusual value.

The bench model is stated to be the largest

selling drill press of this type made by the company and it is a

thoroughly efficient tool sold at the reasonable price of $15,

which gives it unusual value.

It is a rigid, strongly, built, accurate

machine. This type is equipped with a hand feed that is

thoroughly adequate where the amount of drilling is not large

and is necessary in doing delicate work and where the speed of

feeding has to be constantly under strict control.

The speed of

this tool can be instantly changed by turning the knurled sleeve

and the ratios are from 1-1/2 to 1 and 4 to 1.

It has an extension crank from 3 to 6 inches

radius and is finished with a three-jaw Star chuck with

protected springs to hold around shanks up to 1/2 in.

The cast iron frame is unusually strong and

three frame bearings hold the drill spindle and feed screw.

A wrench is included to fit all nuts on the

tool, the overall length of which is 24 in., and the maximum

height 9 in.

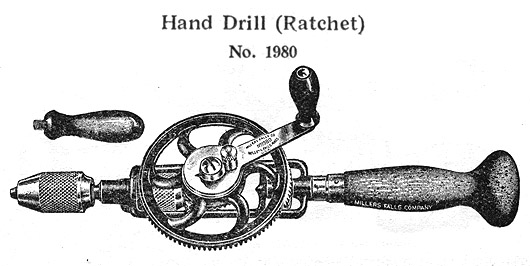

The Model 1980 Ratchet is a large sized drill

with both a ratchet and change of speed.

It takes round shank drills up to 3/8 in., so it

can be used for many kinds of large drilling ordinarily done by

a breast drill, as well as the smaller drilling usually done by

a small hand drill.

The hollow handle end is of mushroom shape to

take the place of breast plate for use against the body. With

some mechanics and men who do not have a great difference in

work this one size of tool will serve every drilling purpose.

The ratchet makes it possible to work in cramped

places and the hollow end handle is quickly detached and will

hold twist drills up to the full capacity of the chuck. No

drills, however, are furnished with the tool.

The ratchet is shifted from right to left, or

vice versa, by giving a half turn to the cap of a small boss on

the crank handle. The speed is changeable by moving a knurled

barrel by pressure of the thumb and operates instantly without

any manipulation of the crank.

The gears are cut, the pinions being of steel

and enclosed for protection, and there is an equalizing bearing

to counter act the outward thrust of the larger gear, the ratios

of which are the same as the Model 210 Bench Drill.

This model is also equipped with a Star

three-jaw chuck and holds drills up to 3/8 in. The springs in

this chuck are located away down in the base where they cannot

be reached by the shank of a drill and jammed or knocked out of

place.

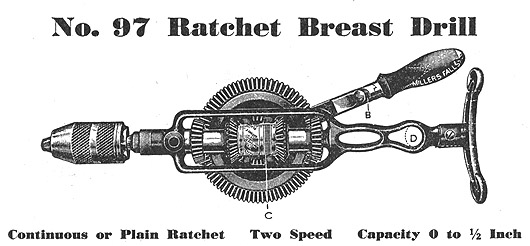

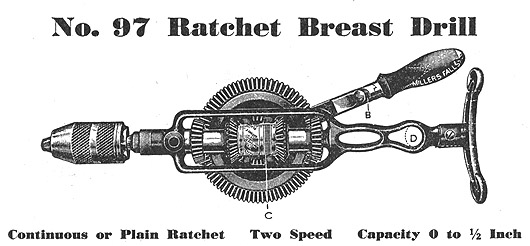

The illustration gives a good description of the

Model 97 Ratchet Breast Drill. This drill is especially popular

amongst automobile mechanics because of its straightening crank

and continuous ratchet which makes it possible to work in

practically any position.

This drill has an easily adjusted ratchet that

has five different actions:

-

The neutral position which gives the

drill the ordinary direct drive ratchet action;

-

Ordinary right hand action in which the

chuck stops turning on the backward stroke of the handle;

-

Ordinary left-hand ratchet action;

-

Continuous right-hand ratchet action in

which the chuck turns continuously to the right on both the

forward and backward strokes of the crank;

-

Continuous left-hand action.

The speed is instantly changeable without

removing drill from the work by moving the knob on the crank

handle. The gear ratios are even and 2-3/4 to 1. The fast and

slow speeds have separate bearings which greatly reduce the

friction and increase the power of the tool and there is also a

double gear drive resulting in very steady action.

All the gears have cut teeth and the small gears

are made of steel. In conjunction with the bearings there is a

take-up nut so that any wear in the bearings can be provided for

and further than this the fast and slow speeds are separated by

bushings so that one will not directly drag on the other.

The crank handle is adjustable for use as an

ordinary crank or as a straight lever for ratchet action in

cramped quarters or for putting greater power into the stroke

and is easily switched from one position to the other by a half

turn of the crank handle.

The breastplate is of special design to give a

handhold for steadying the tool in awkward and out-of-the-way

places. This action is performed simply by loosening a blind

screw and turning the plate parallel to the large gear. It is in

that position shaped to fit the hand and has a finger hole to

give an extra grip. A large auxiliary breast plate is provided

that can be easily clamped over the regular plate and gives

greater comfort and power for doing heavy work.

This drill also has the three-jaw chuck of Star

pattern well removed from any chance of jamming or being knocked

out of place, and will take drills up to 1/4 in.

Automobile Trade

Journal, Vol. 25, October 1920,

(Philadelphia: Chilton

Co.)

Related Info

Wiktor A. Kuc

December, 2016

We want to hear from you - write to:

info@wkFineTools.com

The bench model is stated to be the largest

selling drill press of this type made by the company and it is a

thoroughly efficient tool sold at the reasonable price of $15,

which gives it unusual value.

The bench model is stated to be the largest

selling drill press of this type made by the company and it is a

thoroughly efficient tool sold at the reasonable price of $15,

which gives it unusual value.