The article below is one of a very few that can be found in

the popular press of the 19th and 20th Centuries attempting

to present Millers Falls Co. to a larger audience. However,

the informational value of this article is tinted with

glaring “sales pitch” approach taken by the magazine’s

editors. Hence, facts presented here need some

scrutiny.

At least one instance, the story on a Star Hack Saw

presented here is blatantly skewed and untruthful. I

included a brief explanation on this matter at the end of

the article.

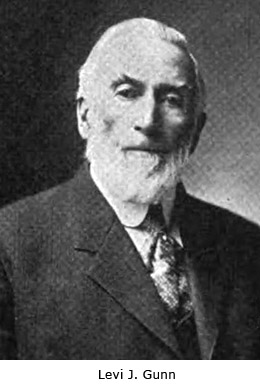

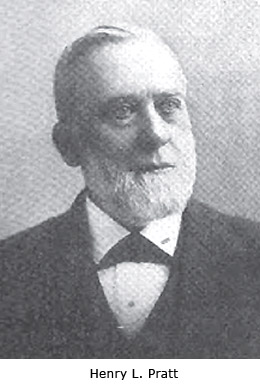

Despite some inaccuracies, the article still has a good value

– it is the only source of pictures of the top management of

the company from the most interesting time period in its

existence. Unfortunately, there is no picture of Charles

Amidon, one of the founders of the company. WK

In a bowl in the hills of the Connecticut River valley in

Massachusetts lie the works of the Millers Falls Co. Nature has

graced the spot with rugged and wooded hills, steep valleys and

the swift flowing Millers River. One might select it as the

country home of poets instead of the seat of a bustling and

thriving manufacturing plant.

The rural setting makes all the more conspicuous

the appearance of the Millers Falls Co.’s plant in its midst.

There is trimness about the buildings and ground enclosed,

park-like, with high iron fence and substantial stone posts that

be speaks a well ordered establishment.

The

Millers Falls Co. is the product of New England pluck and the

ability to seize an opportunity. In the early sixties, Levi J.

Gunn and Charles Amidon, fellow - workmen in the employ of the

Greenfield Tool Co., at Greenfield, Mass, decided to venture

alone, and erected a small manufacturing plant at North Parish,

so called, in Greenfield. The

Millers Falls Co. is the product of New England pluck and the

ability to seize an opportunity. In the early sixties, Levi J.

Gunn and Charles Amidon, fellow - workmen in the employ of the

Greenfield Tool Co., at Greenfield, Mass, decided to venture

alone, and erected a small manufacturing plant at North Parish,

so called, in Greenfield.

They had courage and little money. Funds were

borrowed to pay maturing loans, first here, then there. Peter

was robbed to pay Paul. It was such a hard struggle to keep the

insignificant enterprise afloat that the partners contrived in

every way possible to avoid expense.

Mr. Amidon made an old-fashioned overshot wheel

and used a rope, instead of a belt, for transmission, and when

water power failed in midsummer, the shop was practically

closed.

At first, they made clothes wringers, but so

limited were their resources that $300 was the high-water mark

of this stock.

In 1865, Wm. Barber of Windsor, Vt., brought to

the partners a sample of a new kind of bit brace. This was the

bit brace known to the present day as the Barber brace. The name

has stuck not only to the product of the Millers Falls Co., but

has come to be applied to this type of bit brace even though

later made by other manufacturers.

Mechanics were, however, wedded to their

old-fashioned wooden bit braces and it was only by means of

canvassers that the new bit braces found a foothold.

As at first made, they were entirely from malleable iron with a

bulge in the sweep as a handle. Eighteen braces were considered

a day’s work, but in a few years the business was fairly

established, and the product multiplied many times.

Mr. Pratt Arrives

Meanwhile, the $300 stock of wringers was stored

in Mr. Gunn’s barn. A fire wiped this out without insurance.

Then the plant at North Parish was destroyed in the same way,

but the partners, undismayed, resumed business almost at once

under the roof of the Greenfield Tool Co. Here again, a fire

occurred and destroyed the new beginnings.

Previous

to this time, Henry L. Pratt, a man of some means, had become

interested in the enterprise and had aided the increasing

business by adding small tool holders and other devices of an

amateur nature. Previous

to this time, Henry L. Pratt, a man of some means, had become

interested in the enterprise and had aided the increasing

business by adding small tool holders and other devices of an

amateur nature.

For years he had been in the lumber business,

and in traveling up and down the country had become familiar

with various mill sites. He had often remarked that someday the

water power of the Millers River would be very valuable, and

counselled that Gunn & Amidon move to Grout’s Corner, now known

as Millers Falls, on this river.

Although in the wilderness, the spot was on the

turnpike from Troy, N. Y., to Boston and boasted a noted

hostelry. Herders en route to Boston made a point of reaching

Grout's Corner for a night’s stop, and the wild and roistering

bands that gathered there made the place historic in the

neighborhood. Little old men from their farms away back in the

hills jogged down occasionally to imbibe excitement in this

spirited company.

No one, however, became so hilarious or

visionary as to imagine that, in the next half century, this

aboriginal spot would be transformed by the ever-increasing

plant and business of the Millers Falls Co. Into such

surroundings came Mr. Pratt and his associates; sober, canny

men, with eyes keen to opportunities and no dreams, but

practical ideas of founding an enduring and successful

manufacturing business.

The spot selected for their operations was

overgrown with a dense forest and it was necessary to clear off

the property. A one-story brick factory two hundred and fifty

feet long and fifty feet wide was erected. This still remains,

with another story added, in the midst of many greater and more

modern buildings - a steady, silent growth, and still expanding.

So incredulous were the natives that the town, now subsisting on

the enterprise of the Millers Falls Co., then refused to build a

short bridge over the Millers River and finally the company had

to stand half of the expense of an old-fashioned covered wooden

structure that was built.

The start at Grout’s Corner was made in 1868.

The company was then incorporated under the name of Millers

Falls Manufacturing Company. The business was successful from

the start and continued under the above name until 1872, when it

was merged with the Backus Vise Co., of Windsor, VT., under the

name of Millers Falls Company.

|